(Was Model 220 through 224)

Standard Features:

- Wafer Flange (Fits Between Two Class 150 ASME Flanges)

- Full Protective Shield Around Inner Glass Tube

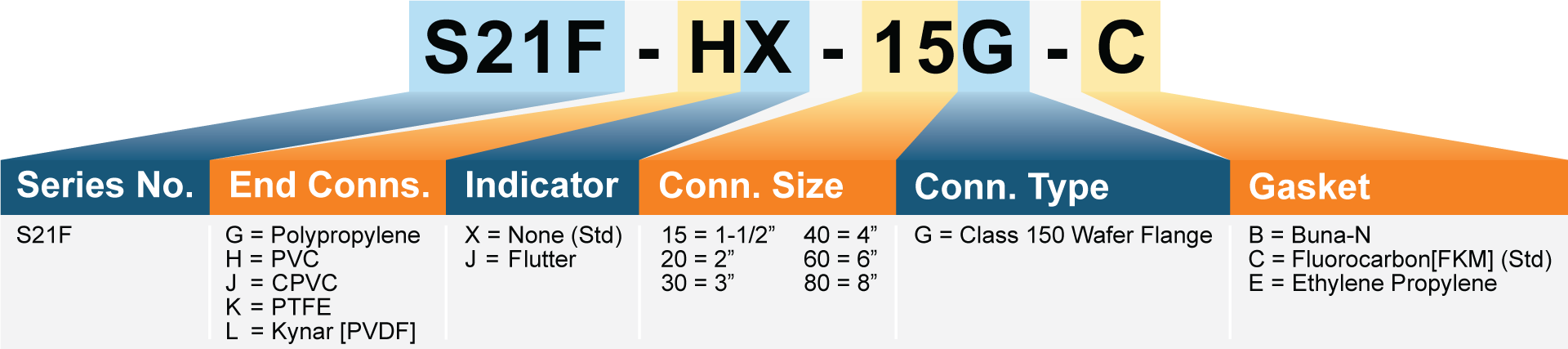

Connection Sizes:

- 1-1/2” to 8” Wafer Flanges

Standard Wetted Materials:

- End Fittings: Polypropylene, PVC, CPVC, or Kynar® (PVDF)

- O-Ring Seals: Fluorocarbon (FKM)

- Glass: Borosilicate Cylinder

Standard Non-Wetted Materials:

- Hardware: 18-8SS

- Shield: Acrylic

Options:

- Buna-N or Ethylene Propylene (EPDM) Gaskets

- Flutter Device (PTFE/Fluorocarbon)

Application Notes:

- Steam Service: Not acceptable

- Potable Water: The glass has not been tested and certified to be acceptable for potable water

- Vacuum Service: Suitable for vacuum service

- Gaseous Service: Not designed for lightweight gases

- Corrosion: Before ordering, verify all materials of our sight flow indicators are compatible with the service media(s), intermittently used cleaners, the environment, and cleaning processes in conjunction with the temperatures and pressures of the application(s) and future applications. Ernst Instruments does not make chemical compatibility recommendations. Compatibility is the responsibility of the user.

Replacement Parts:

- Please contact our sales department

Alternate Equipment:

- Fully Shielded Metal & PVC Indicators: Series S18F

- Teflon®Lined/Insert Indicators: Series S19F