Glass Applications

- Sight Windows, Flow Indicators and Observation Equipment

- Pressure Vessels/Tanks

- Furnaces and Ovens

- Custom specifications cut to size

*Dependent on corresponding thickness or diameter

Disc Edges: ground or water jet cut

Rectangle Edges: water jet cut, except under 1/4” are hand cut and swipe

- See matrix for more sizing details

- Smaller and larger sizes available upon request

- Tighter tolerances available upon request

Note: All Glass should be protected from thermal shock, and shielding is recommended.

Annealed Borosilicate Glass: Style 530 Disc & Style 531 Rectangle

Tempered Borosilicate Glass Disc: Style 538 Disc & Style 539 Rectangle

- Schott Borofloat Borosilicate Flat Glass

- Industrial grade for chemical process plant equipment and laboratories

- Highly chemically resistant with low thermal expansion

- Highly resistant to water; neutral, acidic and saline solutions; chlorine, bromine, iodine and organic substances

- Exceptional clarity

- Optional PFA Coating of glass (not recommended for thermal cycling applications)

Cobalt Blue Furnace Glass Disc: Style 532 Disc & Style 533 Rectangle

- Heat Resistant Borosilicate

- For Furnace Observation

- Reduces glare when observing flame, smoke, and ash intensity in power plants and marine boilers

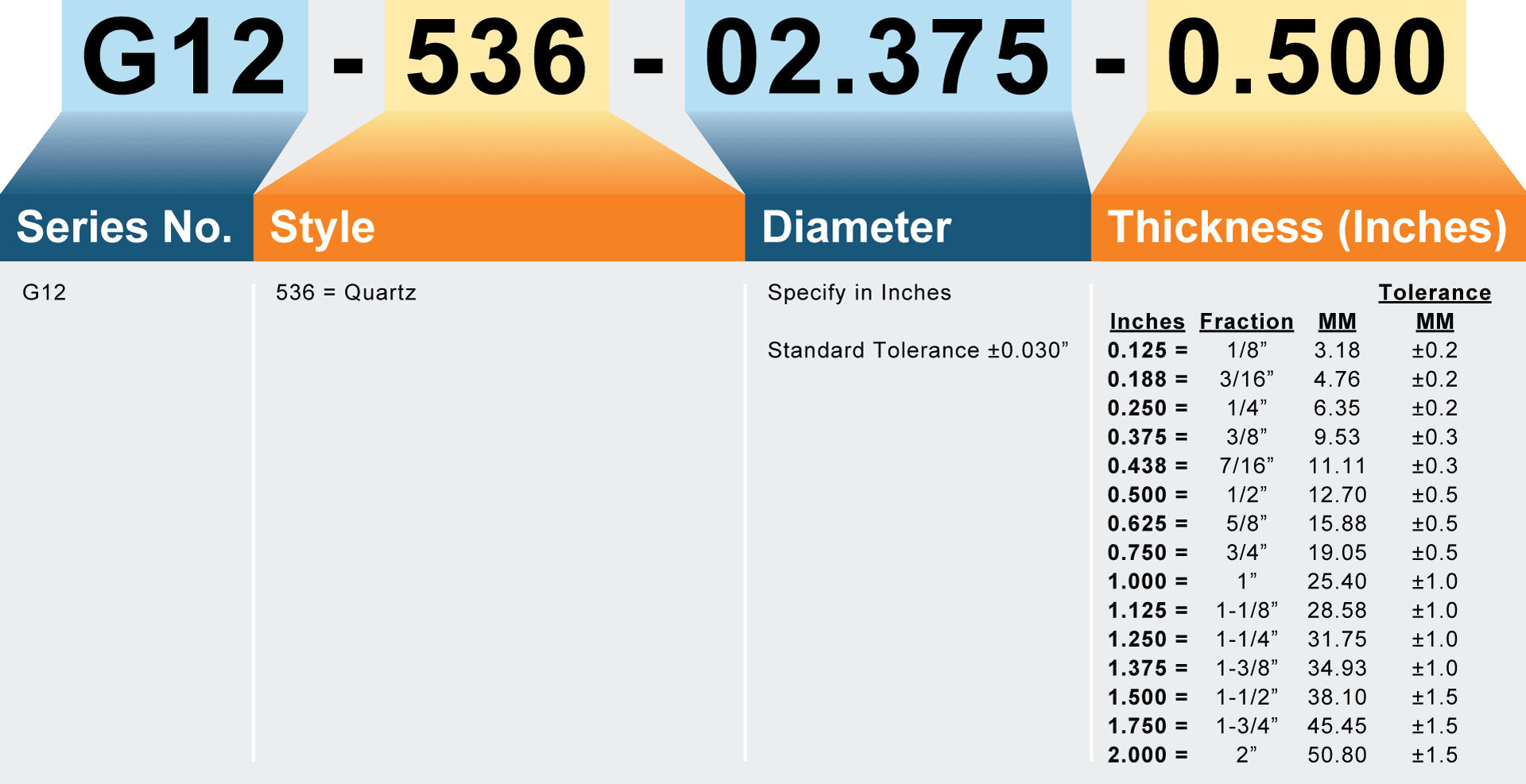

Style 536 – Quartz Glass: Style 536 Disc & 537 Rectangle

- GE 124 commercial grade quartz (Clear Fused Quartz)

- For high temperature industrial and laboratory applications

- Chemically unreactive in general use applications

- Extremely low coefficient of expansion

- High thermal shock resistance

- Excellent clarity

Tempering

Tempering increases the strength of glass and helps it overcome the damaging effect of scratches and other surface defects. Glass is heated to a specified point above its annealing temperature, then quickly quenched causing the surface to shrink and harden. While the interior cools more slowly the exterior tries to shrink, putting itself in tension and creating a compressive stress on the surface. Thus, the mechanical and impact strength as well as the thermal shock resistance are improved resulting in a glass than can withstand higher pressures.

Style 538 Tempered Glass 1/4″ thick or less are Heat Strengthen and are not fully tempered, thus have reduced ratings.

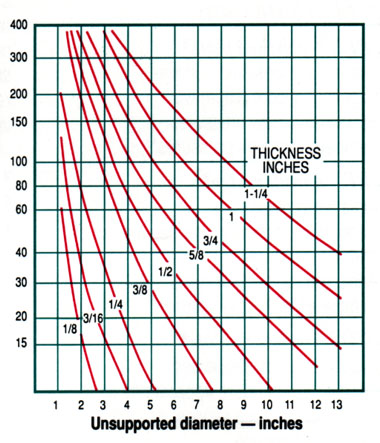

Pressure Chart for Annealed Borosilicate Discs

Maximum Recommended Working Pressure* (PSIG)

*Pressure ratings are not guaranteed but are estimates for reference only. Glass ratings are limited to the ratings of the equipment the glass is installed in and the various conditions of the applications they are used for.

Application Notes

- Steam Service: Requires Mica protection

- Vacuum Service: Acceptable with properly designed equipment and sealing

- Compatibility: Before ordering, verify that the glass is compatible with the design, media(s), cleaning solutions, and the environment of the application and future applications. Ernst Instruments does not make compatibility recommendations. Compatibility determinations, corrosion or otherwise, are the responsibility of the user.

Some medias reduce the useful life of gauge glass by chemical action, such as Hydrofluoric Acid (HF), hot concentrated Phosphoric Acid (H3PO4), Sodium Hydroxide (NaOH) and Potassium Hydroxide (KOH) above 125°F, steam or superheated water above 250°F. Alkaline solutions attach glass very slowly at room temperatures, but as temperature is increased over 100°F, the corrosion rate rises rapidly. Steam can etch or erode glass thus weaken the glass.

WARNING: This product can expose you to certain chemicals, which are known to the State of California to cause cancer or birth defects or other reproductive harm. For more information go to: www.P65Warnings.ca.gov