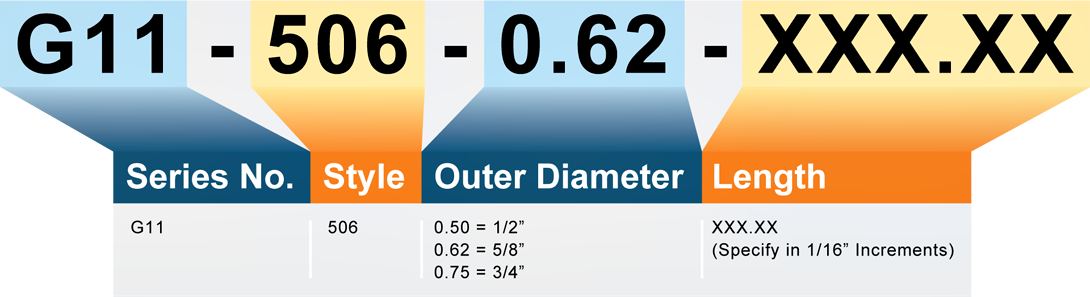

SERIES G11 - STYLE 506

DURAN® HIGH PRESSURE REDLINE TUBULAR GAUGE GLASS

WE CUT TO ANY LENGTH!

Why Redline?

Redline striped glass makes clear liquids such as water very easy to see compared to using clear glass tubes, especially when viewing from a distance. By positioning the redline stripe side of the glass opposite the operator’s viewing position, the redline stripe is magnified by the liquid in front of it. Thus the redline will appear very wide where liquid is present and very narrow where liquid is not present.

Features

- Red and White Lined tubular glass for high pressure and steam applications

- High Quality Borosilicate Duran® Glass manufactured by Schott North America, Inc.

Options

- For lengths over 72” Redline Tape can be applied – see Style-505

- Tighter length tolerances less than ±1/16”, please inquire

Application Notes

- Steam Service: Limited to 24” Lengths

- Vacuum Service: Acceptable with properly designed valves and seals

- Compatibility: Before ordering, verify that all the materials of construction, pressures, temperatures, and any other specifications are compatible with the design, media(s), cleaning solutions, and the environment of the application and future applications. Ernst Instruments does not make compatibility recommendations. Compatibility determinations, corrosion or otherwise, are the responsibility of the user.

Some medias reduce the useful life of gauge glass by chemical action, such as Hydrofluoric Acid (HF), hot concentrated Phosphoric Acid (H3PO4), Sodium Hydroxide (NaOH) and Potassium Hydroxide (KOH) above 125°F, steam or superheated water above 250°F. Alkaline solutions attach glass very slowly at room temperatures, but as temperature is increased over 100°F, the corrosion rate rises rapidly. Steam can etch or corrode glass thus weaken the glass tube.

WARNING: This product can expose you to certain chemicals, which are known to the State of California to cause cancer or birth defects or other reproductive harm. For more information go to: www.P65Warnings.ca.gov

Alternate Glass Tubing

- 503 Low Pressure Clear

- 505 High Pressure Clear

- 507 Heavy Wall Clear

- 508 Heavy Wall Redline

- 514 Heavy Wall Glass Cylinder

- 513 Metric Glass Tubing

Alternate Plastic Tubing