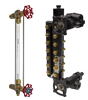

SERIES H14B

HIGH PRESSURE ARMORED LEVEL GAUGES

Benefits & Features

- Maximum protected level gauges using 34mm wide glass

- Pressures up to 4000 PSIG @ 100°F, Temperatures up to 800°F

- Standard gauges rated up to 300 PSIG @ 421°F Saturated steam

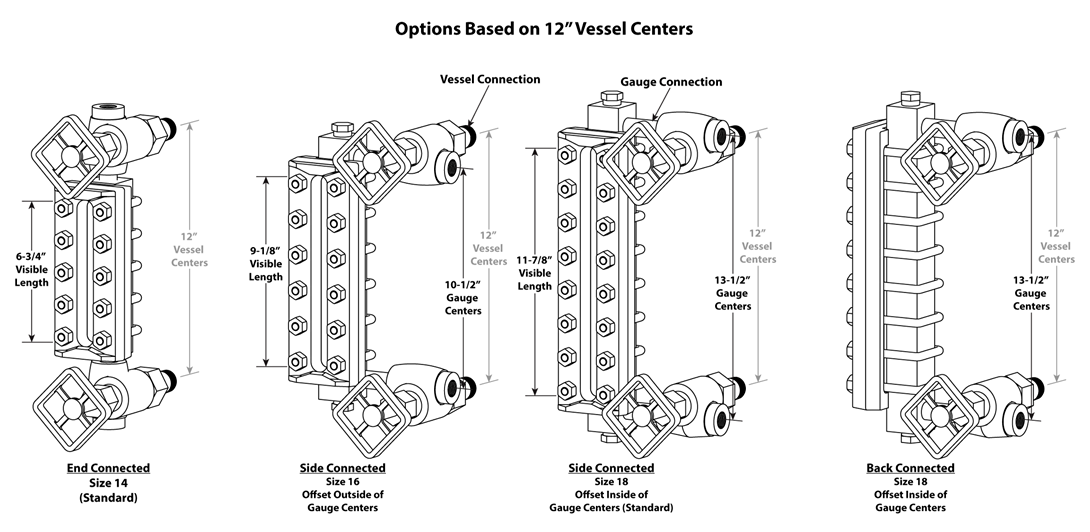

- Standard Gauges with 1/2” FNPT End Connections (in stock)

- Steam Configurated Gauges for over 300 PSIG available in transparent gauges (side connected configurations in stock)

- Optional 3/4” FNPT connections and 1/2” or larger flanged connections available in end, side, or back connected configurations

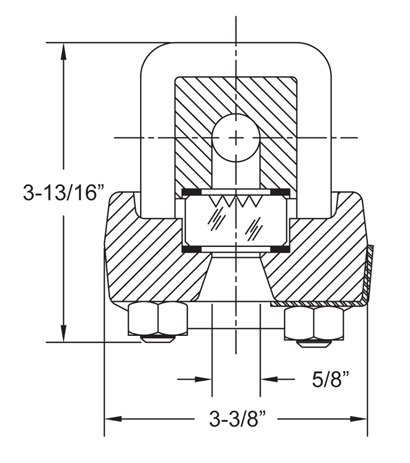

- Reflex Gauges provide economical level indication using one glass and per chamber/section. The level of the media in the vessel appears black and the prismatic glass reflects back silver where media is not present. Light is only required in the front of the gauge.

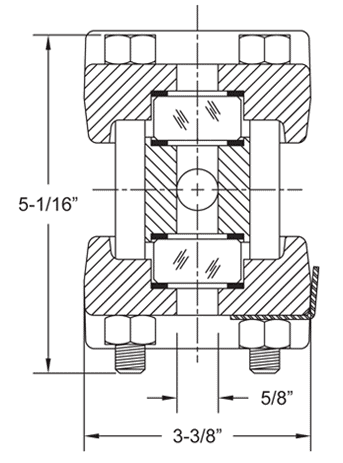

- Transparent Gauges utilize two glasses, one on each side of the chamber for direct visual observation of the vessel’s media, level, quality, and color. Light is required from the back.

- Wetted Parts conform to NACE MR0175 & MR0103

- All parts listed in ASTM & ASME B31.3

- Carbon Steel Covers are Shrouded to Protect the Glass Edges

- All Gages feature a one-piece chamber design, regardless of length

Reflex vs Transparent

- Reflex Gauges provide economical level indication using one glass per section. The level of the media in the vessel appears black and the prismatic glass reflects back silver where the liquid is not present. Light is only required in the front of the gauge.

- Transparent Gauges utilize two glasses, one on each side of the chamber for direct visual observation of the vessel’s liquid, level, quality, and color. Light is required from the back.

Options

- Reflex gauges with side or back connections in 3/4” FNPT, 1/2” and larger flanged connections (contact factory)

- Transparent gauges with side connections in 3/4” FNPT, 1/2” and larger flanged connections (contact factory)

- Aluminosilicate glass for higher temperature ratings (contact factory)

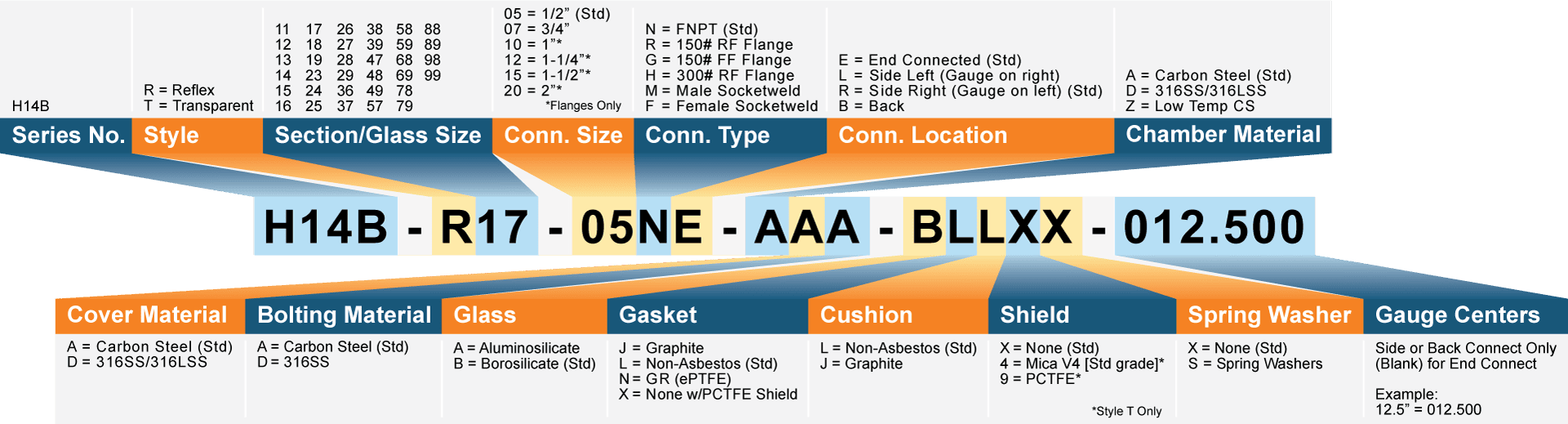

- See Matrix for standard options

Application Notes:

- Saturated Steam Service: See Ratings charts or contact factory

- Potable Water: Carbon Steel wetted materials are not suitable for potable water, 316SS chambers are suitable

- Vacuum Service: Suitable

- Gaseous Service: Not acceptable

- Compatibility: Before ordering, verify all materials are compatible with the service media(s), intermittently used cleaners, the environment, and cleaning processes in conjunction with the temperatures and pressures of the application(s) and future applications. Ernst Instruments does not make chemical compatibility recommendations. Compatibility is the responsibility of the user and/or specifying party.

WARNING: This product can expose you to certain chemicals, which are known to the State of California to cause cancer or birth defects or other reproductive harm. For more information go to: www.P65Warnings.ca.gov

Replacement Parts

- Please contact our Sales Dept. sales@ernstinstruments.com or call 888-943-5000