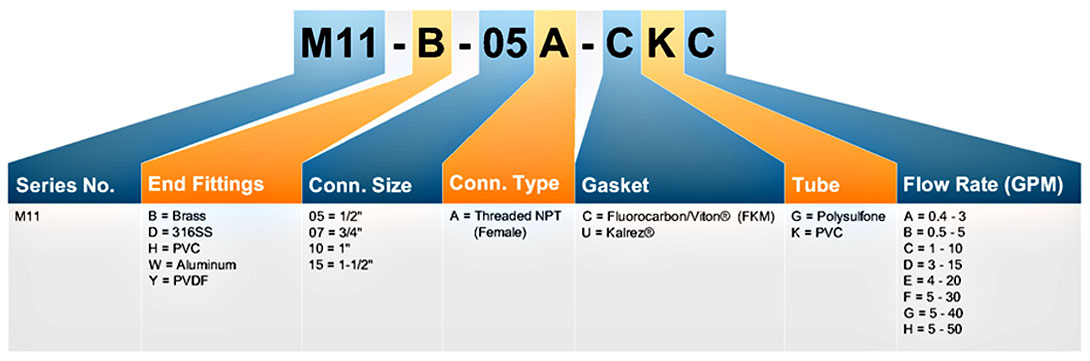

| End Fittings | Brass | 316SS | Aluminum | PVC | PVDF | 316SS | PVC |

| Tube/Housing | PVC | PVC | PVC | PVC | Polysulfone | Polysulfone | PVC |

| Seals | Viton® | Viton® | Viton® | Viton® | Viton® | Viton® | Viton® |

| Spring & Shaft | 316SS | 316SS | 316SS | 316SS | 316SS | 316SS | Titanium |

| Shaft Retainer | PVC | PVC | PVC | PVC | Polysulfone | Polysulfone | PVC |

| Piston | PVC | PVC | PVC | PVC | Polysulfone | Polysulfone | PVC |

| Housing (Optional) | Polysulfone | Polysulfone | Polysulfone | - | - | - | - |

| Piston (Optional) | Polysulfone | Polysulfone | Polysulfone | - | - | - | - |

| Seals (Optional) | - | - | - | - | Kalrez® | Kalrez® | - |

| Sizes (NPT Female) | 1/2" 3/4" 1" 1½" | 1/2" 3/4" 1" 1½" | 1/2" 3/4" 1" 1½" | 1/2" 3/4" 1" 1½" | 1/2" 3/4" 1" 1½" | 1/2" 3/4" 1" 1½" | 1/2" 3/4" 1" 1½" |

| GPM* (LPM)* | GPM* (LPM)* | GPM* (LPM)* | GPM* (LPM)* | GPM* (LPM)* | GPM* (LPM)* | GPM* (LPM)* |

| Low Flow Rate Scale Options For Fluids In Sizes 1/2", 3/4" or 1" | 0.4 - 3 (GPM Only)

0.5 - 5 (2 - 20)

1.0 - 10 (6 - 38)

3.0 - 15 (5 - 55) | 0.4 - 3 (GPM Only)

0.5 - 5 (2 - 20)

1.0 - 10 (6 - 38)

3.0 - 15 (5 - 55) | 0.4 - 3 (GPM Only)

0.5 - 5 (2 - 20)

1.0 - 10 (6 - 38)

3.0 - 15 (5 - 55) | 0.4 - 3 (GPM Only)

0.5 - 5 (2 - 20)

1.0 - 10 (6 - 38)

3.0 - 15 (5 - 55) | 0.4 - 3 (GPM Only)

0.5 - 5 (2 - 20)

1.0 - 10 (6 - 38)

3.0 - 15 (5 - 55) | 0.4 - 3 (GPM Only)

0.5 - 5 (2 - 20)

1.0 - 10 (6 - 38)

3.0 - 15 (5 - 55) | 0.4 - 3 (GPM Only)

0.5 - 5 (2 - 20)

1.0 - 10 (6 - 38)

3.0 - 15 (5 - 55) |

| High Flow Rate Scale Options For Fluids In Sizes 3/4", 1" or 1½" | 4 - 20 (15 - 75)

5 - 30 (10 - 110)

5 - 40 (15 - 150)

5 - 50 (20 - 200) | 4 - 20 (15 - 75)

5 - 30 (10 - 110)

5 - 40 (15 - 150)

5 - 50 (20 - 200) | 4 - 20 (15 - 75)

5 - 30 (10 - 110)

5 - 40 (15 - 150)

5 - 50 (20 - 200) | 4 - 20 (15 - 75)

5 - 30 (10 - 110)

5 - 40 (15 - 150)

5 - 50 (20 - 200) | 4 - 20 (15 - 75)

5 - 30 (10 - 110)

5 - 40 (15 - 150)

5 - 50 (20 - 200) | 4 - 20 (15 - 75)

5 - 30 (10 - 110)

5 - 40 (15 - 150)

5 - 50 (20 - 200) | 4 - 20 (15 - 75)

5 - 30 (10 - 110)

5 - 40 (15 - 150)

5 - 50 (20 - 200) |

| Accuracy (Of Full Scale) | ±5% (.4 - 3 GPM ±7%) | ±5% (.4 - 3 GPM ±7%) | ±5% (.4 - 3 GPM ±7%) | ±5% (.4 - 3 GPM ±7%) | ± 5% | ± 5% | ±5% (.4 - 3 GPM ±7%) |

| SCFM (SLPM) | SCFM (SLPM) | SCFM (SLPM) | SCFM (SLPM) | | | |

| Low Flow Rate Scale Options For Air @ 90 PSIG In Sizes 1/2", 3/4" or 1" | 5 - 50 (200 - 1400)

15 - 90/100** (250 - 2500)

20 - 135 (600 - 3900) | 5 - 50 (200 - 1400)

15 - 90/100** (250 - 2500)

20 - 135 (600 - 3900) | 5 - 50 (200 - 1400)

15 - 90/100** (250 - 2500)

20 - 135 (600 - 3900) | 5 - 50 (200 - 1400)

15 - 90/100** (250 - 2500)

20 - 135 (600 - 3900) | - | - | - |

| High Flow Rate Scale Options For Air @ 90 PSIG In Sizes 3/4", 1" or 1½" | 20 - 200

(500 - 5500)

30 - 300

(1000 - 8000)

40 - 400

(1000 - 11000)

50 - 500

(2000 - 14000) | 20 - 200

(500 - 5500)

30 - 300

(1000 - 8000)

40 - 400

(1000 - 11000)

50 - 500

(2000 - 14000) | 20 - 200

(500 - 5500)

30 - 300

(1000 - 8000)

40 - 400

(1000 - 11000)

50 - 500

(2000 - 14000) | 20 - 200

(500 - 5500)

30 - 300

(1000 - 8000)

40 - 400

(1000 - 11000)

50 - 500

(2000 - 14000) | - | - | - |

| Max Pressure for Fluids (Standard Materials) | 200 PSIG @ 70°F | 200 PSIG @ 70°F | 200 PSIG @ 70°F | 200 PSIG @ 70°F | 150 PSIG @ 150°F | 250 PSIG @ 230°F | 200 PSIG @ 70°F |

| Max Temperature for Fluids (Standard Materials) | 125°F @ 75 PSIG | 125°F @ 75 PSIG | 125°F @ 75 PSIG | 125°F @ 75 PSIG | 150°F @ 150 PSIG | 230°F @ 250 PSIG | 125°F @ 75 PSIG |

| Max Pressure for Air (Standard Materials) | 100 PSIG @ 70°F | 100 PSIG @ 70°F | 100 PSIG @ 70°F | 100 PSIG @ 70°F | - | - | - |

| Max Temperature for Air (Standard Materials) | 125°F @ 35 PSIG | 125°F @ 35 PSIG | 125°F @ 35 PSIG | 125°F @ 35 PSIG | - | - | - |

| Pressure Drop (At Full Scale) | 4 PSIG | 4 PSIG | 4 PSIG | 4 PSIG | 4 PSIG | 4 PSIG | 4 PSIG |

| Conn. To Conn. Length | 7" | 7" | 7" | 7" | 7" | 7" | 7" |

| Typical Applications | Cooling, Process, Weld, Scrubber, Condensate, Ground/Pond and Pool Water Compressed Air, Nitrogen Blanketing & Purging | Cooling, Process, Weld, Scrubber, Condensate, Ground/Pond and Pool Water Compressed Air, Nitrogen Blanketing & Purging | Cooling, Process, Weld, Scrubber, Condensate, Ground/Pond and Pool Water Compressed Air, Nitrogen Blanketing & Purging | Cooling, Process, Weld, Scrubber, Condensate, Ground/Pond and Pool Water Compressed Air, Nitrogen Blanketing & Purging | Deionized (DI) Water, Ultra-Pure Water, Distilled Water, Demineralized Water | Deionized (DI) Water, Ultra-Pure Water, Distilled Water, Demineralized Water | Municipal & Industrial Water & Wastewater Treatment for Disinfection, Clarification, De-chlorination and Neutralization |