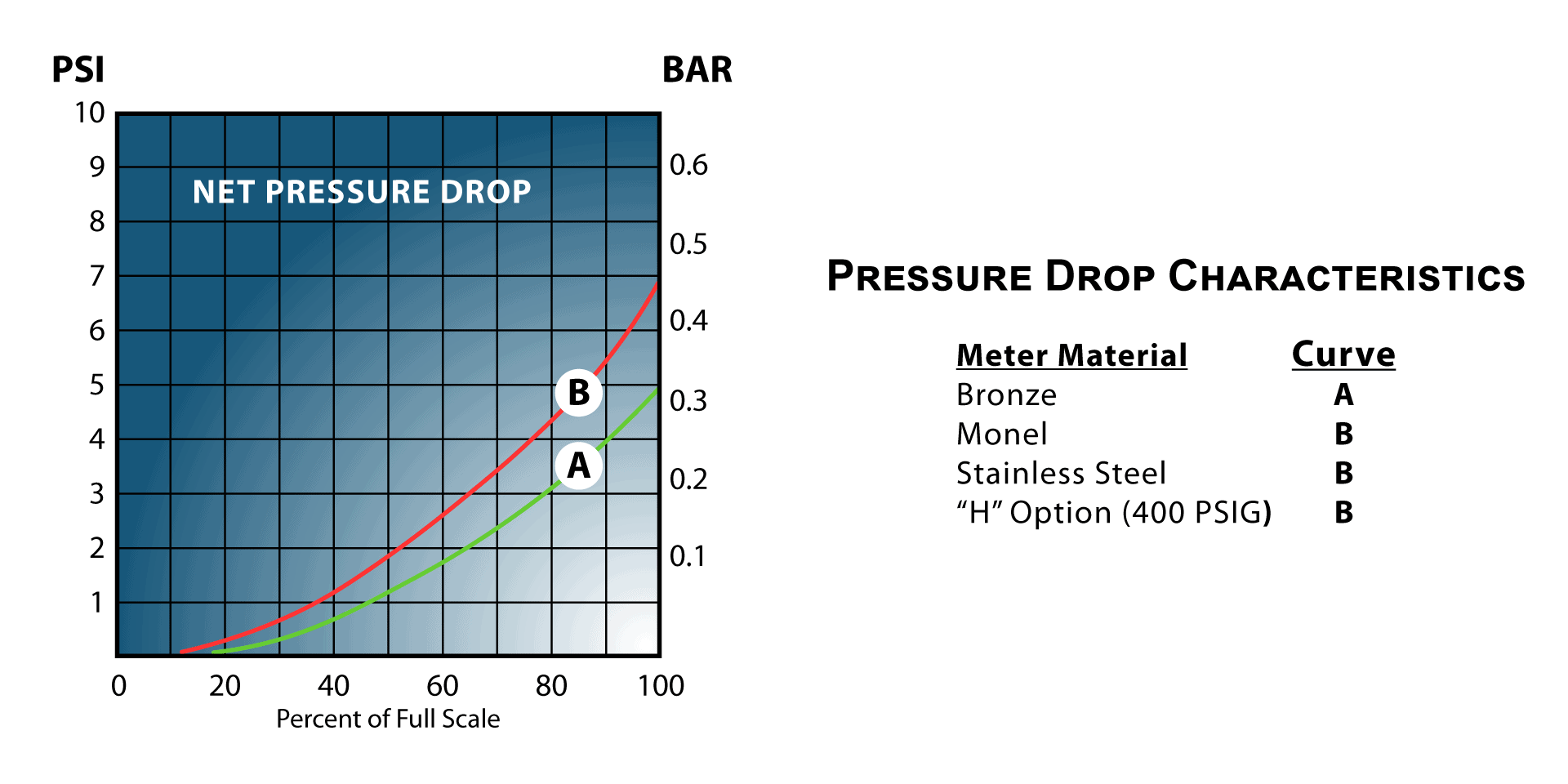

(Was Model 300, 301, 302), (Was Model 300W, 301W, 302W)

Meter Type

Differential Pressure Flow/Meter for fluids or gases

How It Works

Measures flow based on pressure differential created across a built-in nozzle

Features

- Large 3-1/2” Analog Dial Display

- Mechanical – requires no power

- Factory calibrated for Liquid or Gas

- Display Head can be mounted to read horizontally left or right of vertical piping or above or below of horizontal piping. (Below is ideal for steam applications.)

Applications*

*Always verify chemical compatibility with the body materials, the seals and all internal wetted parts.

- All 3 body materials are suitable for:

- Water, including Deionized (DI), Demineralized & Distilled Water, Steam, most Oils & Solvents, and many low viscosity fluids

- Compressed Air, Oxygen, Carbon Dioxide and many other non-toxic compressed gases

- Monel is suitable for:

- Sea Water and Brackish Water

- Up to 25% Nitric Acid

- Other acids and alkalines

Sizes

- 1/4″ to 8″

Options and Application Notes

Options

- EPR, Viton®, Teflon® Seals

- 350°F, 400 PSIG (120°F Max for Digital Meters)

- LPM, SCFM, Nm³/H, Lbs/HR Scales

- Factory Calibration for Stable Specific Gravities other than 1.0

- Factory Calibration for Stable Viscosities under 500 cP

- Non-Standard Flow Rates

- Aluminum Housing with Plastic or Glass Crystal

- 4-20mA Output Signal

- Saturated Steam Service (120 PSIG Max.)

- Compressed Gas Service

- Ammonia Service

- Custom Scales (including Dual Scales)

- Peak Flow Indicator Dial

- Remote Readouts

- Panel Mount Meter Case (1½” or smaller only)

- 1 or 2 Reed switches SPDT

- Two Set Point Relays (High/Low)

- Cleaning for Oxygen Service

- 24VDC Power Supply

- NIST Calibration Certificates 4 to 200 GPM Full Scale up to Size 3″ (at time of order)

- Expedited Shipping (please contact our Sales Dept.)

- BSP Connections in Bronze or Stainless Steel

Application Notes

- Saturated Steam Service: Acceptable when configured for Saturated Steam Service (Max 120 PSIG)

- Potable Water: Not acceptable

- Vacuum Service: Not acceptable

- Gaseous Service: Acceptable when configured for Gases

- Installation: 10 pipe diameters of straight pipe required Upstream, No requirements downstream. Keep medias from freezing at all times in meter. Do not subject meter to water hammer. These Digital Meters require 24VDC power. We recommend that they are installed by an experienced installer or electrician.

- Corrosion: Before ordering, verify all materials of our flow meters are compatible with the service media(s), intermittently used cleaners, the environment, and cleaning processes in conjunction with the temperatures and pressures of the application(s) and future applications. Ernst Instruments does not make chemical compatibility recommendations. Compatibility is the responsibility of the user and/or specifying party.

ORDERING REQUIREMENTS FOR METERS

For Liquids Please Specify

- Body Material: Bronze, 316SS, or Monel

- Seals: Buna-N, Ethylene Propylene, Viton®, or Teflon®

- Connection Size: 1/2″ to 8″

- Flow Range: See Scale options

- Flow Direction:

- Horizontal Left to Right

- Horizontal Right to Left

- Vertical Up mounted on Left or Right

- Vertical Down mount on Left or Right

- Media: If other than Water

- Pressure: Between 10 PSIG to 400 PSIG

- Temperature: Between -80 to 350°F

- Specific Gravity: At normal operating temperature (If under .95 S.G. or over 1.05 S.G.)

- Viscosity: At normal operating temperature (If over 5 cP)

For Gases Please Specify

- Body Material: Bronze, 316SS, or Monel

- Seals: Buna-N, Ethylene Propylene, Viton®, or Teflon®

- Connection Size: 1/4″ to 8″

- Flow Range: See Scale options

- Flow Direction:

- Horizontal Left to Right

- Horizontal Right to Left

- Vertical Up mounted on Left or Right

- Vertical Down mount on Left or Right

- Gas: Name of gas

- Pressure: Specify one specific or average pressure between 10 PSIG to 400 PSIG at meter inlet

- Temperature: Specify one specific or average temperature between -80 to 350°F at meter inlet

- Saturated Steam: Specify one specific or average pressure between 10 PSIG to 120 PSIG at meter inlet